- HOME

- 3D SOFTWARE

- PATIENT - SPECIFIC IMPLANTS

- Materialise aMace

Materialise aMace

Go for the long-term solution

Personalized acetabular implants designed to break the revision cycle.

Augment the predictability, trust the outcome.

Descarcă broşura

Request an offer

Up to 27% of hip revisions are re-revisions due to a suboptimal fixation and suboptimal biomechanical reconstruction of the joint when combining standard components. What’s even worse, hip re-revisions are 3 times more likely to fail compared to a primary acetabular revision. Fortunately, you can break this downward spiral. Meet Materialise aMace, the personalized one-piece solution with a 98% implant survival3 and 100% patient satisfaction rate.

How we enable you to break the revision cycle

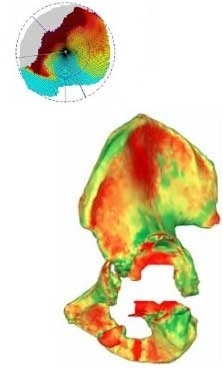

Unique 3D Visualization of Hip

The aMace solution starts with a detailed preoperative planning, including a unique patient-specific analysis of the hip. Based on the segmented CT scan, our highly-trained clinical engineers implement A.I.-enabled technology to quantify the radial acetabular bone loss and visualize the available bone stock by measuring the thickness of the bone and cortex over the entire surface.

Patented drill guides

The 3D-printed drill guides have been designed to be easy to use, while giving you the confidence of executing the detailed screw planning. Its innovative guide design fits perfectly in the acetabular implant and allows you to optimize primary fixation by placing the required cross-fixated screws as indicated by the detailed preoperative plan. Based on the extensive experience gained through patient-specific hip and knee guides, we offer you a novel tool that adds ease to even the most complex acetabular procedures.

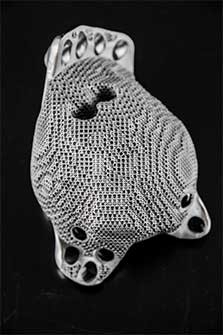

Trabecular biocompatible augment

Tap into the advantages offered by a defect-filling trabecular augment made of a highly biocompatible material: Ti6AI4V ELI (a titanium alloy). The back of the light-weighted integrated cup and flanges consist of a porous structure that mimics bone properties designed to improve secondary fixation through bone ongrowth and ingrowth. Moreover, a personalized design intends to maximize bone preservation and allows for the adaptation of the one-piece implant to the patient instead of the other way around.

Easy-to-use digital platform to collaborate and order online

Materialise SurgiCase is a web-based 3D planning platform that enables clinical teams to upload, plan and collaborate with highly-qualified clinical engineers on cases in an easy-to-use and secure online location. Hospital staff can upload images securely knowing that our privacy regulations meet all the GDPR requirements. Whether you’re working at the hospital or from home using your computer or tablet: accessing the preoperative plan, giving feedback or approving the 3D design – SurgiCase makes it as easy as it gets.

What is the process?

Week 1

- CT SCAN

Upload the CT scan to the SurgiCase 3D planning platform. In order to help you achieve a predictable outcome, it is important that the scans meet the requirements stipulated by the Materialise Scan Protocol.

- 3D ANALYSIS

After visualizing the patient’s bone defects and present components in 3D, our clinical engineers map out the acetabular defect in terms of missing bone and thickness. Next, we perform an acetabular bone loss analysis so as to compare the patient’s situation with a healthy acetabulum.

- 3D PLAN AND DESIGN

Our clinical engineers design the actual implant based on the ideal center of rotation (COR) and bone preservation. We provide you with relevant measurements, a unique bone quality map and determine the ideal screw positioning. You review the design and provide your feedback through SurgiCase. While the overall majority of preoperative plans are approved from the start, we’re always there to discuss and adapt the implant design if needed.

Week 4+1

- PRODUCTION

Once approved, the patient-specific implant design is produced in our medical-certified facilities. We also provide you with 3D-printed drill guides, an implant trial model and accurate bone model of the patient.

- SHIPMENT

The complete package, including the case report, surgical technique, surgical poster and sterilization instructions, is shipped to your hospital – ready for surgery.

Feedback

Customer Feedback Form

Register for Our Newsletter