- HOME

- 3D PRINTERS

- POLIMERS

- SL

- Stratasys SL Neo450

Stratasys SL Neo450

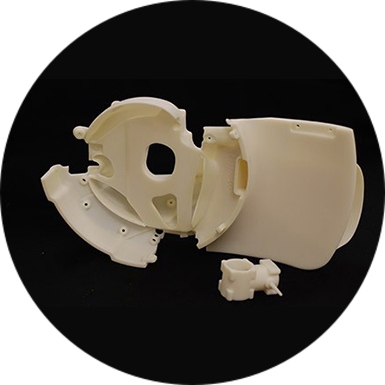

Print functional models, prototypes, rapid tooling and master patterns with the state-of-the-art Neo® stereolithography 3D printer range.

Print functional models, prototype patterns and production parts with the state-of-the-art Neo Stereolithography 3D printer range.

British designed and manufactured by RPS engineers, the reliable and proven Neo® 3D printer builds high-quality parts with superior surface quality, accuracy and detail.

Descarcă broşura

Request an offer

Print functional models, prototypes, rapid tooling and master patterns with the state-of-the-art Neo® stereolithography 3D printer range.

Print functional models, prototype patterns and production parts with the state-of-the-art Neo Stereolithography 3D printer range.

British designed and manufactured by RPS engineers, the reliable and proven Neo® 3D printer builds high-quality parts with superior surface quality, accuracy and detail.

Reduce finishing time by up to 50%

The Neo450 produces highly accurate parts with unparalleled industry quality. Optimising the machine design and utilising the latest cutting-edge technology available for laser and scanners, our beam delivery system produces exceptional layer-to-layer alignment repeatability. The printed parts are dimensionally accurate, with exceptional sidewalls and crisp feature resolution.

Versatile and functional

The Neo® is available in a smaller 450x450x400 platform. Offer different build options and modes to suit all applications.

Faster build speeds

The high-power laser processes any 355 nm SL resin while maintaining maximum productivity between services. Build speeds are enhanced with carefully developed and efficient software. Dynamic beam shape control is standard throughout the Neo® range, with variable option available for even greater build speeds.

Proven reliability and quality assurance

British designed and manufactured, the Neo is carefully engineered throughout using state of the art technology, proven components and aesthetic finishes.

Minimise downtime, increase productivity

The Neo450 utilises an integrated UPS system with intelligent monitoring control.†† With the UPS system, receive notification of any downtime for greater peace of mind. If the UPS battery runs out, a controlled build pause and shut-down will automatically occur, minimising any further disruption.

Open resin system

An open material system means users are not restricted by the usual parameter constraints, offering the ability to utilise any 355 nm hybrid resin chemistry.

Enhance workflow efficiencies with Titanium™ software

Intuitive software is developed for simplified daily operation. or more functionality for detailed builds when required. Customer suggestions and feedback are encouraged, driving user focused software updates.

Part traceability and data reportingfor your application

Titanium™ software helps you capture build history, parameter detail and part traceability data for further insight and reporting. Get further insight such as hardware or resin usage easily, via Microsoft Excel® export

Outstanding accessible service and support

If required, highly skilled Nutechnologies engineers are available to support on-site the next business day◊ or via remote diagnostics to help when needed.

| NEO 450e | Neo 450s | ||

| Laser | 1 Watt | 2 Watt | |

Laser and Scanning System |

355 nm, solid-state frequency Tripled Nd: YV04 |

355 nm, solid-state requency Tripled Nd: YV04 |

|

| Beam Focus | Dynamic | Dynamic and Variabil | |

| Beam Size | 250µm | 80-750µm | |

| Scanning Speed | Up to 10m/s | Up to 10m/s | |

| Layer resolution | 50 to 200µm* | 50 to 200µm* | |

| Minimum feature size | 0,3mm in X & Y†/0,4mm in Z† | 0,15mm in X & Y†/0,4mm in Z† | |

| Build modes | SD | HD and SD | |

| Build speed |

In like-for-like comparison, build Times are up to 40% shorter with the NEO™ 450s |

||

| Accuracy | Dimension 100mm ±0,1%† | ||

| Material Compatibility | Open resin system - Compatible with 355nm SL resin | ||

| Capacities |

Build (XYZ) |

Short: ** 17.72 × 17.72 × 1.97 in. (450 × 450 × 50 mm) Half: ** 17.72 × 17.72 × 7.87 in. (450 × 450 × 200 mm) Full: 17.72 × 17.72 × 15.75 in. (450 × 450 × 400 mm) |

|

| Vat Fill |

Short: 10 US gal (95 lb‡ ) [38 ltr (43kg‡ )] Half: 22 US gal (203 lb‡ ) [82 ltr (92kg‡ )] Full: 37 US gal (348 lb‡ ) [141 ltr (158 kg‡ )] |

||

| Software | Operating System | Windows 10 Pro | |

| Input file format | SLC | ||

| Control Software | Titanium™ | ||

| Remote Editor | Titanium Assistant™ (Optional) | ||

| Conectivity | Ethernet | Fully compliant with IEE 802,3; IEEE 802.3u; IEEE 802.3ab. | |

| WIFI | Fully compliant with IEEE 802,11 b/g/n †† (optional) | ||

| USB Port | USB 3.1 | ||

| Features & Build options |

Build validation Build time estimator Material usage estimator Open build parameters enabling any material to be processed On-the-fly parameter adjustment & part deletion Upper surface build quality optimization Bubble remover with an automated option Scheduled start |

||

| Advanced services & Reporting tools |

Industry 4.0 compliant Full part traceability Logging of machine utilization; build history; parameters; material usage; formatted data export System & build status email notifications Onboard camera Resin viscosity tracking User level access control Scheduled lighting |

||

| Support | Remote diagnostics | ||

| Electrical requirements |

110∼120 Volt, 60 Hz |

300W typical operation, 550 W Max | |

| 220∼240 Volt, 50 Hz | 700W typical operation, 1300 W Max | ||

| UPS | 10∼20 mins of system up-time with Intelligent Control (Optional) | ||

| Environmental requirements | Temperature range: 20-23ºC, max rate change ±1ºC/hr. Relative humidity 20-50% non-condensing | ||

| Dimensions (WxDxH) | 1050x1225x1900mm | ||

| Weight | Printer | 600kg | |

| Vat (empty) | 100kg | ||

| Regulatory Conformity | ICES-3 | ||

Materials for Stratasys SL Neo450

Feedback

Customer Feedback Form

Register for Our Newsletter