- HOME

- 3D PRINTERS

- POLIMERS

- POLYJET

- Stratasys Polyjet J5 MediJet

Stratasys Polyjet J5 MediJet

The all-in-one medical printer

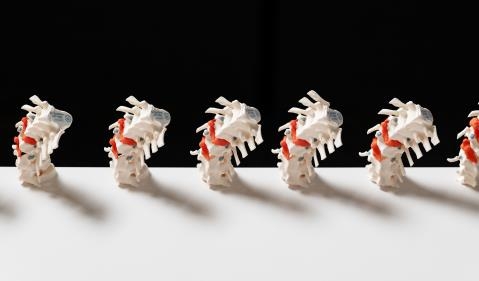

With multi-material, multicolor and biocompatible capabilities in a single print tray, MediJet™ sets a new standard for medical modeling.

Descarcă broşura

Request an offer

Accelerate medical innovation.

With multiple materials and multicolor capabilities, academic medical centers, hospitals, and medical device companies can create brilliantly vivid pre-surgical planning models, education and training models, medical device development models and drilling and cutting guides* that are sterilizable and biocompatible.

- 510(k) cleared with leading segmentation software companies

- ISO 13485 Certified

Multi-material, multicolor, sterilizable & biocompatible capabilities

MediJet is setting a new standard for medical modeling. With multiple materials and multicolor

capabilities, academic medical centers, hospitals and medical device companies can create

brilliantly vivid anatomical models, and drilling and cutting guides* that are sterilizable and biocompatible.

Print more models with less handling — all within a small footprint

Service multiple departments and create more medical models with less handling — all within a

small footprint. Print pre-surgical planning models, training and education models, surgical guides

and medical device development models with a certified system — all on one platform. Plus, with a

lower up-front investment and smaller footprint, MediJet™ is economical and compact enough for

small lab spaces.

Simplify your workflow with GrabCAD Print™

Design and increase production of highly accurate and detailed medical models with ease. This

software automatically corrects files and reduces print time with automatic tray arrangement. And a

new feature alerts the user if there has been cross contamination with a biocompatible material.

Improve point-of-care & patient satisfaction

The use of patient-specific 3D printed medical models for pre-surgical planning improves patient

outcomes by reducing complications, decreasing operation time and length of hospital stays.

Plus, patient understanding, consent and satisfaction have been shown to improve with the use of

3D medical models.1, 2, 3

Enhance training & education programs

Synthetic models, animals and cadavers do not always accurately represent the pathology you are

looking to study. Scale up your product demonstrations when training field staff and physicians

on your new medical device by providing models that replicate the disease state your device is

intended to treat. If you’re a teaching hospital, print the exact pathology on-demand and train

anywhere without cadaver storage requirements or ethical concerns associated with animal models.

Applications

- Pre-surgical planning models

- Training and education models

- Surgical guides and tooling

- Medical device development models

Biocompatible rigid transparent (MED610)

Transparent, sterilizable, biocompatible material medically approved for bodily contact.

Biocompatible Opaque (MED615RGD™ IV)

Rigid Ivory, sterilizable, biocompatible material medically approved for bodily contact.

Vero™

Provides unique multicolor capabilities to produce sterilizable, smooth, accurate and realistic models.

DraftWhite (MED837)

Opaque, UV resistant, low-cost model material, which aims to lower the cost of single material applications and bulk color models.

Elastico Clear (FLX934)

Transparent flexible material with Shore A value of 45, with a superior tear-resistant and elongation.

Cost

30% lower cost per part compared to outsourcing.

Time

30% faster print time than comparable printing solutions**.

Color

Brilliantly vivid, multi-material and multicolor capabilities.

|

Product Specifications |

||

|

Model Materials |

Biocompatible materials: n Biocompatible rigid transparent (MED610) n Biocompatible Opaque (MED615RGD™ IV) Rubber like: n Elastico Clear (FLX934) |

Rigid Transparent Colors: n VeroCyan™V n VeroMagenta™V n VeroYellow™V n VeroUltra™ClearS n VeroBlackPlus™ n DraftWhite (MED837) |

|

Supported Sterilization Processes |

Steam (4 minutes at 132 °C), Gamma (25 – 50 kGy), EtO (specifications available upon request) |

|

|

Digital Model Materials |

Unlimited number of composite materials including over 500,000 colors |

|

|

Support Materials |

SUP710™ (Water Jet removable) |

|

|

Build Tray |

Printing area: 1,174cm2 Max Part Size: Up to 140 x 200 x 190mm (5.51 x 7.87 x 7.48 in.) |

|

|

Layer Thickness |

Horizontal build layers down to 18 microns (0.0007 in.) |

|

|

Accuracy |

Deviation from STL dimensions with rigid materials,based on size: under 100 mm – ±150μ; above 100 mm – ±0.15% of part length.* * true for 67% (1 sigma) models printed for future information can be found in the spec sheet |

|

|

Network Connectivity |

LAN – TCP/IP |

|

|

System Size and Weight |

651 x 661 x 1511mm (25.63 x 26.02 x 59.49 in.); 228 kg (503 lbs.) |

|

|

Operating Conditions |

Temperature 18 – 25 °C (64 – 77 °F); relative humidity 30 – 70% (non-condensing) |

|

|

Power Requirements |

100 – 240 VAC, 50 – 60 HZ, 10A, 1 phase |

|

|

Regulatory Compliance |

CE, FCC, EAC |

|

|

Software |

GrabCAD Print |

|

|

Build Modes |

High Quality Speed (HQS) – 18.75μm |

|

Feedback

Customer Feedback Form

Register for Our Newsletter