- HOME

- Post-Processing Systems

- CLEANING

- Powershot C - PolyShot Cleaning

Powershot C - PolyShot Cleaning

The industry standard for easy and efficient part cleaning

Descarcă broşura

Request an offer

- AUTOMATED DEPOWDERING BOOSTS YOUR PRODUCTION CAPACITY

With our proprietary PolyShot Cleaning (PSC) a mid-sized build job can be cleaned in only ten minutes or less. The time you need for part cleaning and the personnel in your production can be significantly reduced. This boosts your effectiveness and efficiency. By investing in automated part cleaning with the Powershot C, up to four manual blasting systems can be easily replaced. PolyShot Cleaning is compatible with all common powder-bed technologies and delivers residue-free parts for brilliant colors.

- GENTLE PART TREATMENT THANKS TO SMART HARDWARE FEATURES

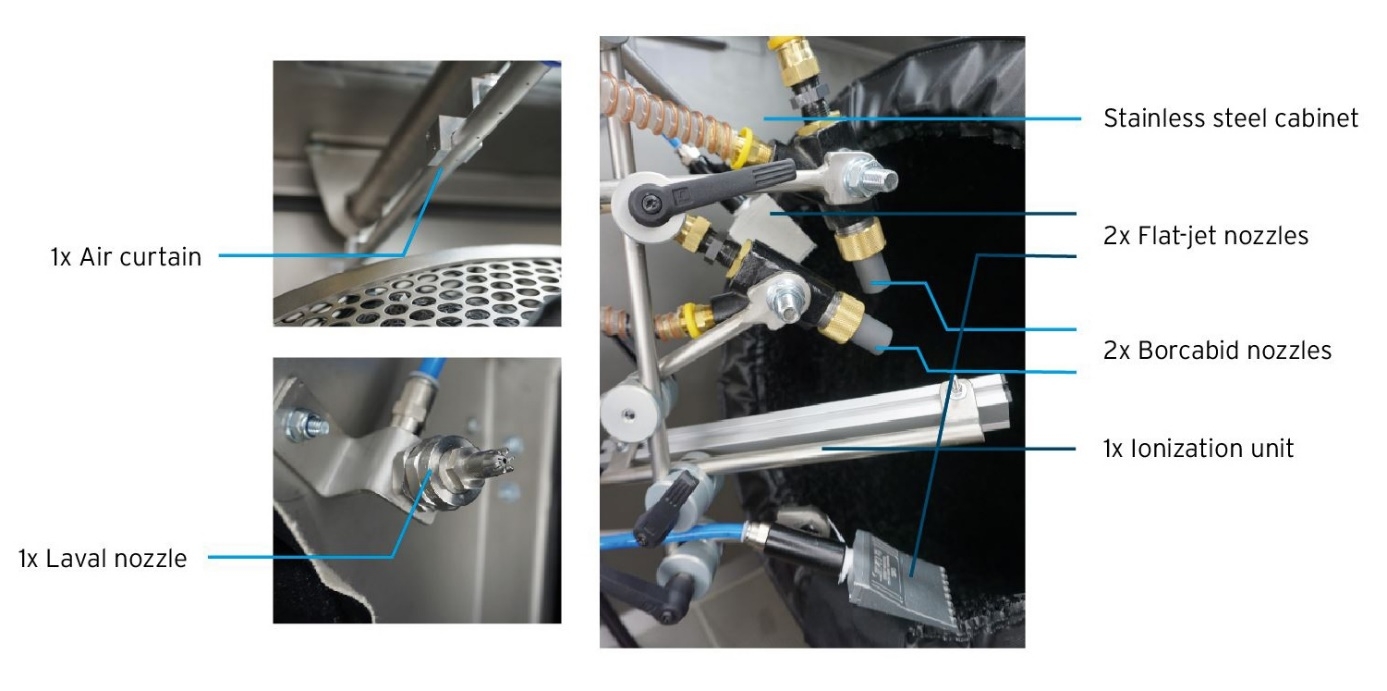

The blasting cabinet of our Powershot C is equipped with a rotary basket and is manufactured from stainless steel. Different blasting nozzles and an ionization unit ensure reproducible results. Couple this with a basket with a soft and replaceable lining protecting the parts from damage during the process. Two simultaneously working blasting nozzles are positioned perpendicular to the rotating basket and the contained parts. The cyclone cleans the blasting media constantly. This configuration guarantees an efficient powder removal.

- ADVANCED OPERATOR CONVINIENCE WITH ENHANCED ERGONOMICS AND PROCESS CONTROL

Experience a new level of process control with a touchscreen and integrated controlpanel. The Powershot C is being operated through a userfriendly interface and pre-installed programs can be started. Individual programs can be configured and saved easily, enabling a fast adaption to your application. With a user-centric design everything can be easily accessed and operated safely. Continuous monitoring allows an efficient and reproducible process.

- CAPACITY PER RUN: MID SIZED BUILD JOB (up to 3/4 of EOS P396 or full HP Jet Fusion 4200/5200 print job)

- SPECIAL NOZZLE SET-UP & AUTOMATED BLASTING MEDIA CLEANING

The combination of blasting and flat-jet nozzles as well as an ionizing unit achieve powder-free parts in just a few minutes. The adjustable high performance cyclone separates the excess powder from blasting media and enables consistent blasting results.

- Proprietary cleaning process with plastic blasting media

- Gentle and efficient powder removal

- Allowing for a wider range of process parameters and precision adjustment than conventional cleaning processes

- Compatible with all common powder-bed technologies and improved depowdering of process challenging materials (e.g. TPU)

Developed for the Print-to-Product Workflow: a residue-free cleaning process for brilliant colors

Feedback

Customer Feedback Form

Register for Our Newsletter